Team Builder: Dave Lenss Wraps 46 Years in Construction

If you ask a group of construction veterans what they’ve built, some will point to a massive complex, an iconic structure, or a technical triumph. Over his 46- year career, Dave Lenss has done all of the above, but he’ll tell you about building teams.

(Pictured above, right: Dave Lenss sits with the preconstruction team he grew from a handful of people to over 20 employees.)

During his time at KA, Dave has mobilized and led projects and people through all manner of challenges, including the growth and integration of KA’s preconstruction team, a multidisciplinary cadre of technical experts that dive deeply into plans for a project long before it breaks ground, fostering successful outcomes among all stakeholders. As he prepares for retirement next month, Dave shares some takeaways from his innovative and collaborative career.

Spanning Multiple Roles

In your career you’ve served in several departments, from project management to business development to executive positions leading companies and regional operations. How has this varied experience informed your work leading KACC’s preconstruction initiative?

DAVE LENSS: I’ve been lucky to have had some unique experiences and a few great mentors during my career. As a PM working in the Minneapolis office of a Canadian-owned company, I was willing to travel which is probably the biggest thing that prepared me for professional growth. Being out of town working with new subcontractors you have to be creative to keep a project moving. Often that meant staying late and working with the superintendent to clean an area up in the building to be ready for a subcontractor to move in the next day. Whatever the job needed done we just stayed and did it.

When I was asked to lead the Minneapolis and Omaha offices that made up our U.S. Operations, that role accelerated my learning as I navigated employee benefits and insurance programs, and maintained a strong work pipeline. It was exciting but stressful.

At the time, preconstruction as we know it today didn’t exist. Companies had estimators, but most work was bid once plans were complete. My favorite call back then was when an architect said, “Good news: you’re the low bidder. Bad news: the project is over budget, and the owner wants us to value-engineer it into budget.” Unfortunately, owners rarely got dollar-for-dollar value back during value engineering processes.

That’s when I began thinking about involving contractors earlier in the design phase to support pricing and keep projects on budget. The process would be smoother, and everyone—the architect, contractor and owner—would benefit.

Joining KA

What motivated you to join KA in 2012?

DAVE LENSS: I first encountered KA in 1993 while working for Penn-Co Construction on a project at MSP Airport. Craig Francois oversaw KA’s airport work, and I worked closely with John Boerboon and Brian Turnquist. Over time, my relationship with KA grew stronger through collaborative efforts.

Later, while serving on the AGC of Minnesota Board of Directors, I got to know Bruce Engelsma during his tenure as Board Chair. That experience gave me insight into KA’s values and its focus on people. When I left Graham, I wanted to return to a company with similar values to Penn-Co, and KA felt like the perfect fit.

North Dakota Operations

You’ve worked extensively in North Dakota. What stands out about that experience?

DAVE LENSS: I’ve always enjoyed working in North Dakota. Owners and subcontractors there understand the challenges of working in remote areas and have a “get-it-done” attitude. Relationships are key in North Dakota. Subcontractors trust you if you treat them well, but if you break that trust, you might as well pack up.

Helping establish KA’s Bismarck office with Ross Wilmes and John Haydon was a career highlight. It required hard work but was incredibly rewarding. We built KA’s brand in cities like Watford City and Williston by engaging with communities and forming strong client relationships. The support from colleagues like John Huenink, Tony Sjolander and Jim Bergren were instrumental in our success.

Growing Preconstruction

You became VP of preconstruction in 2017. What did the team look like then, and how has it evolved?

DAVE LENSS: In 2017, preconstruction consisted of three estimators, two mechanical/electrical/plumbing (MEP) specialists, two building information modeling (BIM) team members, and two building science members—all working in silos. Today, the team has grown to 21 people, including specialists in sustainability and design phase management. This multidisciplinary approach reflects the growing complexity of projects, shorter schedules and increased risks for general contractors.

Expanding MEP Expertise

One of the first growth areas after your arrival was the MEP department. What drove that initiative?

DAVE LENSS: We had secured the 280 Building (Carlton Science Center) at 3M, a complex research facility requiring our MEP’s full-time attention. To fill the gap, we brought on Matt Stringfellow, whose expertise supported multiple teams and demonstrated the value of dedicated MEP specialists. As demand grew, so did the team.

Our MEP group now supports estimating, performs constructability reviews, writes work scopes, levels subcontractor bids, and assists with field installation and closeout. Their contributions ensure smoother project execution and stronger client relationships.

Building Science Contributions

Building sciences was added to the preconstruction team in 2016. How did this new expertise address owner demands?

DAVE LENSS: Originally focused on QA/QC, the building science team expanded under Jon Porter’s leadership to address building performance and energy efficiency. They conduct constructability reviews and evaluate building envelope systems, ensuring materials perform as intended. Their input often leads to product recommendations that enhance building performance and longevity.

BIM/VDC Integration

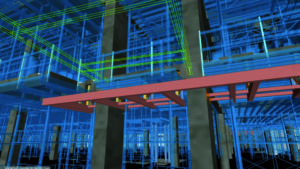

In 2017 Preconstruction added BIM/VDC, or virtual design construction, expertise. Tie those capabilities into the team’s growing expertise.

DAVE LENSS: BIM/VDC supports projects from proposal to closeout. The team assists estimating by analyzing design models and identifying potential conflicts, such as ductwork interfering with light fixtures or pipes clashing with structural beams. By resolving these issues early, we save time and money during construction.

Our reality capture specialist documents and verifies work using drones, scanners and 360 cameras. These tools provide precise, up-to-date project data, enhancing collaboration and accountability.

Digital Twin Technology

The Digital Twin resource launched in 2022. What advantages does it offer?

DAVE LENSS: Digital Twin technology creates measurable 3D models of buildings or spaces using 3D and 360 cameras. For example, a Digital Twin captured before drywall installation provides an exact map of mechanical and electrical components, aiding future renovations. Post-completion, Digital Twins can link specific equipment to the owner’s manuals and equipment maintenance logs, streamlining facility management.

Preconstruction’s Role and Collaboration

How does the preconstruction team interact with project managers, architects and each other?

DAVE LENSS: The earlier the preconstruction team is involved, the better. While estimating is a given for projects, additional services—like design phase management, MEP, building science, and BIM—are utilized à la carte based on project needs. On larger or more complex projects, all preconstruction services are deployed to support the project team comprehensively.

Preconstruction Bootcamp

What is Preconstruction Bootcamp? How did it develop, and what outcomes have you seen?

DAVE LENSS: Before COVID, we noticed that some PEs and PMs lacked foundational estimating skills. We initiated discussions about rotations through Preconstruction, focusing on estimating- with exposure to the other areas of precon. This evolved into a formal training track, with Preconstruction Bootcamp as a key component. The program provides consistent training across KA’s operations, creating well-rounded PMs.

Formalizing Estimating

How has estimating evolved at KA?

DAVE LENSS: Until 2012 or 2013, estimating was largely handled by project managers. Since then, we’ve built a formal estimating team using specialized software to meet growing project demands. Estimators work closely with PMs to ensure accurate cost projections, considering not just what’s shown on the drawings but also what’s required for a successful project.

Design Phase Services

How does the Design Phase team enhance collaboration with architects?

DAVE LENSS: We launched Design Phase services in 2020 with Chad Rempe leading efforts on major projects like NLG III and Warhorse Casino. The team, which now includes Nate Enger and Erica Arne, provides predesign support, site selection guidance, and cost modeling, ensuring projects align with client goals from the outset.

AI Horizons

KA’s preconstruction team has long been recognized for early adoption of leading-edge tech. Give us a glimpse at what the team is exploring today.

DAVE LENSS: AI tools are being used in preconstruction to help clients assess whether a site is suitable for their project. Another new AI platform is being utilized on an upcoming replacement hospital project. It enables the team to value engineering items, and track costs and the overall budget status throughout the design process, fostering collaboration and keeping everyone informed.

The estimating team is also testing an AI takeoff software that automates quantity takeoffs, freeing up estimators for other critical tasks.

Looking ahead, Power BI dashboards are expected to be game-changers, allowing the team to better analyze trends and understand why building designs differ from past projects. This will provide new insights and improve decision-making processes.

Anything else you’d like to share?

DAVE LENSS: I am so thankful for my time at Kraus-Anderson. The people are awesome to work with and the company really does operate by the core values of Integrity, Commitment, Teamwork and Value People.

CATEGORY: Construction